Tube and Pipe Roll Forming Machine: The Complete Guide for Precision Metal Forming

Introduction to Tube and Pipe Roll Forming Technology

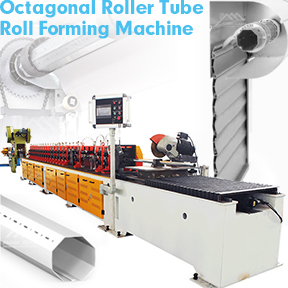

In modern manufacturing, Tube and Pipe Roll Forming Machines are essential for producing high-quality, precision-engineered metal tubes and pipes.These advanced machines transform metal coils into seamless tubes, welded pipes, and structural profiles with unmatched efficiency.Whether for construction, automotive, or industrial applications, investing in the right Tube Roll Forming Machine can significantly enhance your production capabilities.

welded pipe machine

Why Choose a Tube and Pipe Roll Forming Machine?

A Metal Tube Roll Forming Machine offers numerous advantages over traditional manufacturing methods:

✔ High-Speed Production – Form consistent, defect-free tubes and pipes at impressive speeds (up to 120m/min).

✔ Precision Engineering – PLC-controlled systems ensure exact dimensions and tight tolerances.

✔ Material Versatility – Works with steel, stainless steel, aluminum, and coated metals.

✔ Cost Efficiency – Reduces material waste and labor costs compared to manual fabrication.

✔ Customizable Output – Adjustable rollers allow for different diameters, thicknesses, and shapes.

Key Features of an Advanced Tube Rolling Machine

When selecting a Steel Square Tube Making Machine, consider these critical features:

Automated Welding System – Integrated high-frequency (HF) or TIG welding for strong, seamless joints.

CNC Control Panel – Ensures precise adjustments for diameter, thickness, and speed.

Quick-Change Tooling – Switch between different pipe sizes in minutes without downtime.

Laser Cutting & End Forming – Optional add-ons for ready-to-use pipes with clean edges.

Energy-Efficient Design – Low power consumption for sustainable production.

Applications of Metal Oval Tube Cold Roll Forming Machines

Industries that benefit from Metel Tube Making Machines include:

Construction – Structural tubing, scaffolding, and HVAC ducts

Automotive – Exhaust pipes, chassis components, and roll cages

Industrial Machinery – Hydraulic cylinders, conveyor systems, and storage racks

⚡ Energy Sector – Solar panel frames, oil & gas pipelines

Round pipe roll forming machine factory

How to Select the Best Tube and Pipe Roll Forming Machine?

Before purchasing, evaluate:

✅ Production Capacity – Match machine speed (e.g., 30-120m/min) to your output needs.

✅ Material Compatibility – Ensure it supports your required metal type and thickness.

✅ Automation Level – Semi-auto vs. fully automatic with robotic stacking.

✅ After-Sales Support – Look for warranty, spare parts availability, and training.

Boost Your Manufacturing with a High-Performance Pipe Roll Forming Machine!

A Welded Pipe Machine is a game-changer for metal fabricators looking to increase efficiency, reduce costs, and expand product offerings.

Ready to upgrade your production? Contact us today for a customized solution!