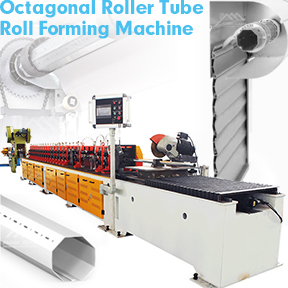

Roll forming is a flexible, responsive and cost-effective alternative to extrusion, press braking, and stamping.Well-suited for customized or standard shape production, roof sheet making machine is a simple process ideal for even the most complex shapes.Roofing corrugated sheet roll forming is an efficient, effective shaping that delivers tight tolerances on complex profiles.

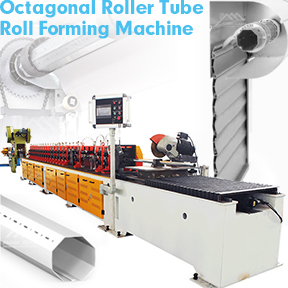

Trapezoidal roof panel roll forming is a reliable, proven approach to metal shaping that is ideal for modern applications. This process uses a continuous bending operation where long metal strips, typically coiled steel, are passed through consecutive sets of rolls at room temperature. Each set of rolls performs incremental parts of the bend to produce the desired cross-section profile. Unlike other metal shaping methods, the roofing tile roll forming process is inherently flexible. Secondary processes can also be integrated into a single production line. Glazed tile roll forming increases efficiency while reducing operational and capital costs by eliminating unnecessary handling and equipment.

The standing seam roof panel forming process is a metal-forming operation that imparts the desired shape to a material strip in a progressive manner.

The material strip could be either ferrous materials such as mild steel, or nonferrous materials such as aluminum, copper, and brass. Some nonmetallic materials like plastic can also be roll formed. These materials are created, by other processes, in sheets, coils, or strips, and supplied to the site of the ridge cap roll forming operation.

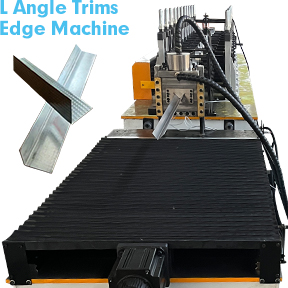

The material strip then undergoes a series of folding or bending processes, or both, to get a desired, engineered shape.

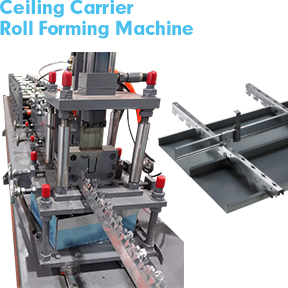

Typical roll forming mills can accommodate material gauges ranging from .010″ up to 0. 250″ thick. The bend radius is largely determined by the ductility of the metal. However, 180-degree bends are commonly achieved with the right material. Deck floor forming machine easily accommodates the integration of secondary operations such as welding, punching and precision laser cutting to optimize production efficiency.

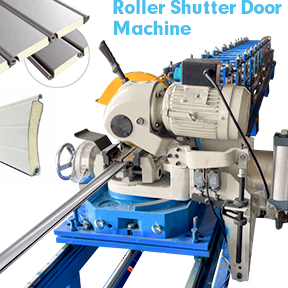

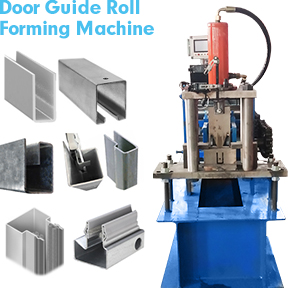

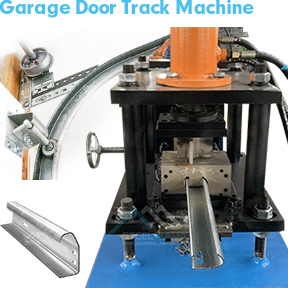

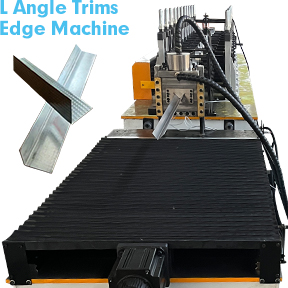

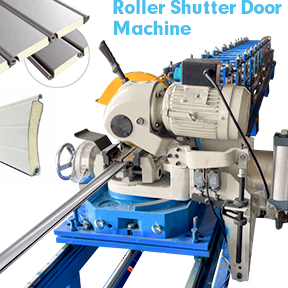

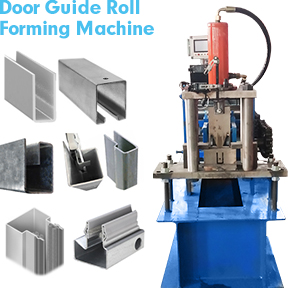

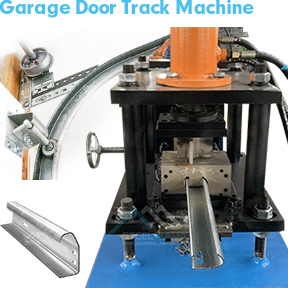

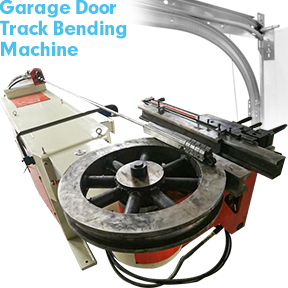

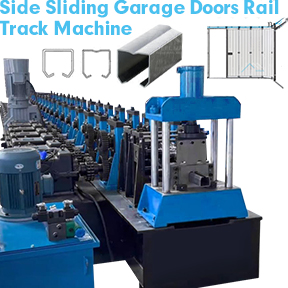

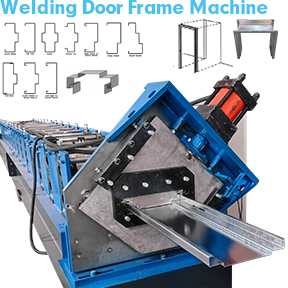

The final shapes contribute to products such as door panels, metal roofing sheets, automotive frames, road barriers, electrical cable supporters, storage racks, and steel drawers.

What are the 7 basic steps in the roll forming process?

The material strip can be fed into the roll forming line using either a pre-cut roll forming line or a post-cut roll forming line. A post-cut roll forming line setup is the most common and described here.

1.The cold c purlin roll forming process begins with the loading of the coil onto the decoiler.

2. The coil rotates to unwind the material strip into the strip straightener.

3. The strip straightener levels the material strip to remove pre-existing defects before the strip enters the press feed unit.

4. The press feed unit feeds and guides the strip to ensure a smooth entry into the pre-punch press. In the absence of the pre-punch press, the press feed unit directly feeds the material strip into the roll forming machine.

5. The galzed tile roof panel roll forming machine uses a series of forming rolls that shape the material strip. Each pair of forming rolls gradually imparts the shape to the material strip.

6. Once the shape is fully formed, the product enters the profile straightener to remove any bends produced during the forming operation.

7. The formed product then enters the cut-off press, is cut to the desired length, and is stacked on a run-out table along with the other formed products from the pu shutter door roll forming line. This is the last stage of the roll forming process.

Several other secondary processes, such as welding, mitering, piercing, and punching operations, can be added to the steel stud track roll forming line.

What are the advantages of the roll forming process?

1.Producing hollow and semi-hollow shapes

2.Reducing handling costs and eliminating post-process finishing by integrating secondary operations into the roll forming line, such as piercing, punching, and bending

3.Ability to roll form different materials into a single product

4.Obtaining superior surface finish without die marks

5.Producing economical and efficiently shaped products

6.Ability to redesign and reuse roll forming tools, such as forming rolls and side rolls, for different products with minimum variation in the design

7.Capable of producing products in higher volumes efficiently when compared to other metal forming processes